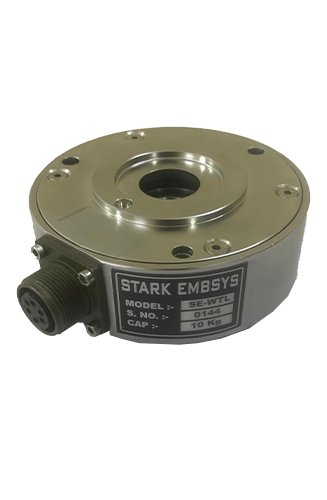

Product Description

How does this work ?

When two strain gauges are placed opposite each other, the length changes proportionally. This

response to change in the

line’s protrusion is measured by a device which is kept on the opposite sides of the line.

The use of paired strain gauges placed on the wire makes it shorter and increases the diameter,

thereby reducing the

resistance. The use of other pair of strain gauges is positioned in a way that extends the cable,

reduces the diameter

and increases the resistance of the wire. While hanging the same weight from the bottom of the

line, place the tension

or stress instead of pressing the line. This will cause the line and strain gauge to act in the

opposite direction yet

experience the same stretching and pressing of cable. This strain can be measured by a Wheatstone

Bridge Configuration.

What is load cell used for ?

Load cell helps to read the electrical units on a regular weighing scale from mechanical force

converted by the

transducer. The amount of load transferred can be easily checked through the weight. There are

load sensors are bonded

with the help of an elastic material or a strain guage. More information is required to understand

the working

principle, type of strain gauges and application.

Load cells are used at the very initial stages that is, during the research and development part.

They can be used for

monitoring the built structure too in the later stages. Depending upon the stage of geotechnical

field, these

instruments are used during previous as well as post construction stages. These instruments ensure

safety of structures

such as dams, tunnels, bridges. Thorough monitoring by geotechnical instruments ensures long term

safety, although the

type of instruments depends on the work.

Specifications

| Material |

Stainless Steel |

| Brand |

Stark Embsys |

| Sensitivity |

2.0 +/- 10% mV /V |

| Temperature operating range |

-40 ~ +70 degree C |

| Input resistance |

400 +/- 10 Ohms |

| Output resistance |

350 +/- 5 Ohms |

| Insulation resistance

|

Less than 2000 M Ohms (@ 50V DC) |

| Recommended Voltage

|

10V (DC/AC) |